Top 10 popular fireproof materials

Perhaps the past few days have been a big shock to families with relatives living in Khuong Dinh mini apartment building – Hanoi. The terrible fire in the night claimed many lives, families lost loved ones, even entire families of 7 were buried in the fire, dreams were unfinished, love affairs were waiting to blossom. flowers, boys and girls who have just set foot in the capital as new students…. The fire on September 12th serves as a reminder to everyone, every family, and construction projects that they should use Fire-resistant materials, and buildings, offices, offices… need to be equipped with fire prevention equipment and fire alarm systems need to be regularly maintained, to be able to warn people when urgent.

Below we introduce to customers some effective fireproof materials that can be used for construction projects.

I. What are fire-resistant materials?

Fireproof or fireproof materials are materials that can withstand high temperatures, helping to slow down or prevent the spread of fires in buildings, offices, factories, etc…

1. Heat-resistant compact material

HPL compact material is a hard sheet with a solid core made of many layers of kraft paper that has been treated with Phenolic resin to increase heat resistance, waterproofing and electrical insulation. The surface of the compact panel is covered with a layer of Melamine to increase gloss and limit the possibility of fire.

This is the line of materials with the best fireproof performance today with many outstanding advantages:

Fire retardant modification: This material is heat resistant up to 800oC. The solid core has absolutely no chance for Oxygen to get inside, minimizing the possibility of fire spreading

Cost savings: This material is being used quite commonly due to its low price, variety of colors and sizes, high durability, and long lifespan.

Super light: Diverse sizes, moderate weight, easy to transport by hand without the need for equipment or machinery.

Perfect adhesion: Easy to bond with other parts such as walls, metal, or between compact panels.

Effective heat and soundproofing: Not only is it fireproof, Compact materials also have an extremely low heat transfer rate, capable of blocking heat and soundproofing.

Good waterproofing: Self-sealing surface filling rate is 100% and water absorption rate is < 0.1%.

Good durability, elasticity and toughness: Able to withstand harsh temperature conditions. Does not attract fungi, termites, or rodents because it is an organic substance that does not contain nutritional value.

Long lifespan: The useful life of compact panels is up to decades

Environmentally friendly: It is an odorless, non-toxic material that helps protect natural resources.

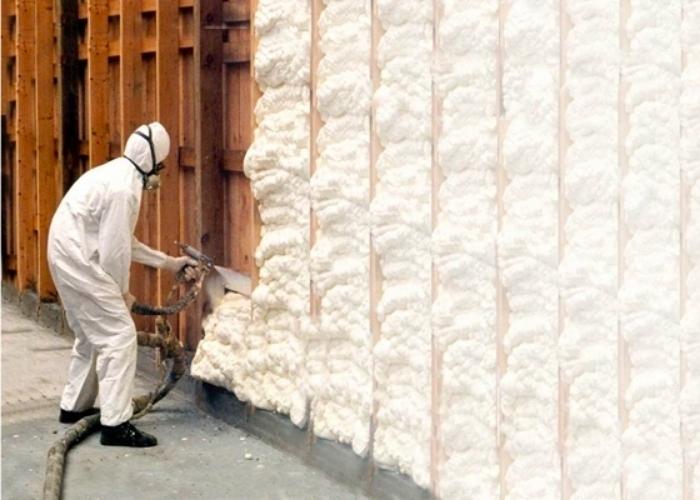

2. PU Foam material is fireproof, heat-insulating, moisture-proof, and sound-proof

PU Foam is an organic compound made up of two components: Polyols and Isocyanate. In which Isocyanate is the hardening agent and Polyols will be the ingredients that determine the soundproofing effectiveness of PU Foam foam.

This compound is mixed with a specialized high-pressure sprayer to create ultra-light, odorless, non-toxic foam and helps protect natural resources by saving energy and reducing emissions into the environment.

This is the line of materials with the best fireproof performance today with many outstanding advantages:

Fire retardant modification: When exposed to temperatures of 800 – 1200 degrees Celsius, CO2 will be produced to extinguish the fire and fire source in 0.7 seconds.

Cost savings: You only spend 1/3 to 1/2 the cost while still ensuring the best and safest fire resistance.

Ultra-light: Allows reduction of up to 49% of structural load and 36% of masonry load. Modified is suitable for inclined, flat, curved roofs and complex structures on all materials.

Perfect adhesion: Can adhere to all material surfaces such as concrete, wood, metal, except non-stick film, PE and PP plastic.

Effective heat and sound insulation: Not only is it fireproof, PU Foam also has an extremely low heat transfer rate of 0.0182 kcal/m.h.oC and prevents sound waves well.

Good waterproofing: Self-sealing surface filling rate is 100% and water absorption rate is < 0.1%.

Good durability, elasticity and toughness: Able to withstand harsh temperature conditions. Does not attract fungi, termites, or rodents because it is an organic substance that does not contain nutritional value.

Long lifespan: PU Foam can last up to 70 years (experimented on a German accelerator)

Environmentally friendly: It is an odorless, non-toxic material that helps protect natural resources.

However, this type of material is not yet popular in Vietnam, currently it is popular in some countries such as Japan, England, France, America, Australia, Korea…..

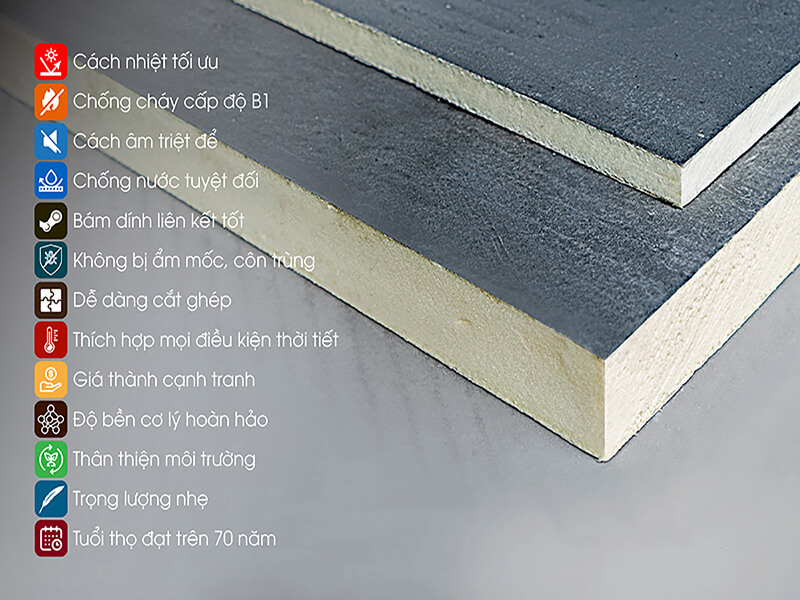

3. Fireproof Takani insulation panels

Takani panels are a material made from PIR material (core) and 02 layers of special polymer cement (on the outer surface) with high heat resistance, insulation, water resistance and fire resistance.

The product is manufactured on Japanese technology lines, with the following advantages:

High fire resistance: The product core is made of PIR material with good fire resistance.

Effective heat resistance: With a heat transfer rate of only 0.021w/m.k, Takani panels provide effective heat resistance and insulation, helping the indoor space become cool and stable while also saving costs. electricity consumption charges.

Light weight: The weight of the product is light, only 1.2 – 2.4kg/m² depending on the thickness of each type, so it is easy to cut, convenient for transportation, and easy and quick construction.

Good soundproofing ability: The PIR core layer has a structure with many air holes evenly distributed with high density, helping Takani panels effectively insulate sound.

Long lifespan: PIR core material is tested at the DIN Test Laboratory (Federal Republic of Germany) resulting in the product having a lifespan of over 70 years.

Waterproof and moisture-proof: Takani panels have a closed-cell structure that is insoluble in water, has low water and vapor absorption, helping to protect “construction health” in tropical climate conditions in Vietnam.

Good mechanical properties: Takani insulation board is an isothermal material, so it does not deform physically when the ambient temperature changes, helping to stabilize the construction surface.

Good adhesion: The surface material is all polymer cement so it has the ability to bond tightly to the construction surface, forming a homogeneous block linked together by a layer of cement mortar.

High aesthetics: Using Takani panels helps create a smooth, uneven exterior wall surface, increasing the aesthetics of the exterior as well as the overall house.

Anti-termites and insects: Takani panels are made from PIR material so they are not attractive to termites and insects.

Taniki plate

With a flexible structure and many outstanding features, Taniki insulation panels are used in heat insulation and heat protection of walls/ceilings/terraces for civil projects. In addition, it is also used as non-load-bearing partitions for offices, rooms and heat-proof corrugated iron roofs for warehouses, factories, etc.

4. Refractory concrete

Concrete is a familiar fire-resistant material in construction projects, formed from mixing ingredients such as cement, water, additives, etc. When solidified into solid blocks, concrete is heat-resistant. High, limited fire spread and less corrosive.

However, high-quality fireproof concrete is susceptible to water penetration, affecting its durability when used for a long time. In addition, this material has a quite high price. This is also a minus point of concrete.

Currently, concrete is mainly used in large projects such as hospitals, high-rise buildings, apartments, etc.

5.Panel prevents fire spread (foam corrugated iron does not spread fire)

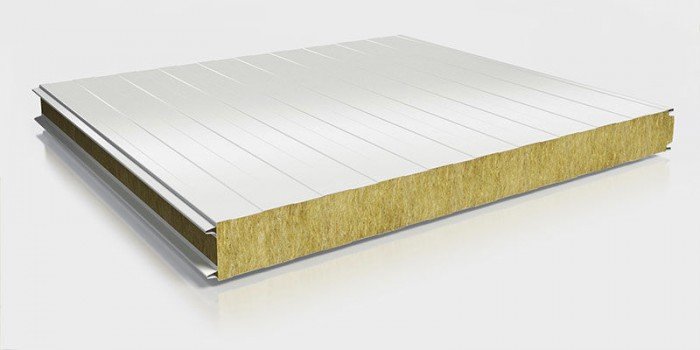

Fireproof panels and fireproof materials are highly appreciated. The panel is composed of 3 layers, including 2 layers of corrugated iron and 1 layer of fire-resistant foam in the middle.

Fireproof panel is a material with many advantages such as high aesthetics, easy cleaning and installation. From there, Panel helps contractors optimize construction costs while still ensuring quality. This material is even tested and recommended by the Department of Fire Prevention and Fighting because of its safety and high effectiveness.

Currently, this type of fireproof panel is commonly used for factories, prefabricated houses, room walls, factory partitions, etc.

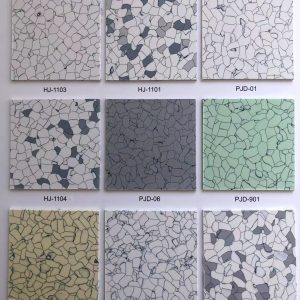

6. Fireproof cool bricks

Fireproof bricks are a useful material and are widely used in construction projects, especially households.

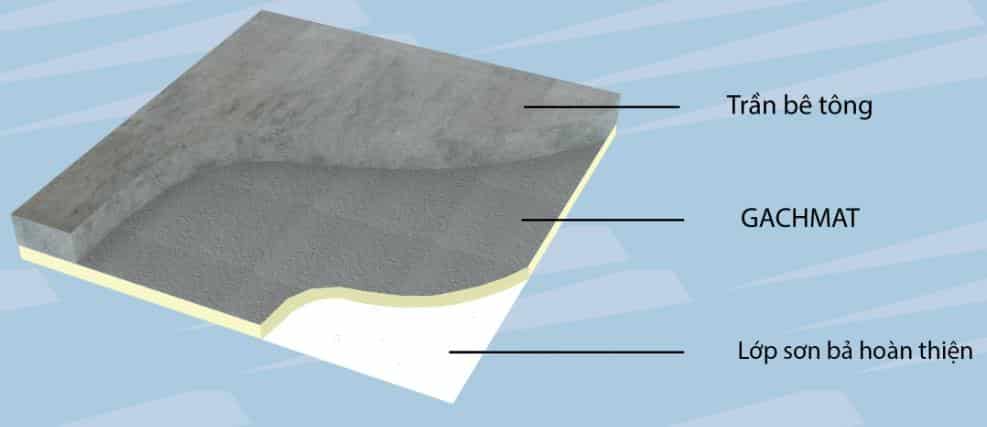

This material has a PU (Polyurethane) layer structure in the middle and a special textured cement layer on both sides. Therefore, cool bricks are non-flammable, non-flammable and have the ability to self-extinguish in the shortest time after being isolated from the source of fire.

Therefore, cool tiles can be applied to all construction and residential spaces such as walls, roofs, ceilings, partitions, floors…

However, the price of the product is quite high, so many investors have gradually switched to using Takani insulation panels with equally effective heat insulation and fire resistance but at a much better cost.

7. Anti-fire paint

Fireproof paint contains ingredients and materials that help reduce the heating process of fire on iron and steel equipment. This helps this fire-resistant material to effectively protect on concrete, wood, and steel surfaces, while also preventing toxic gases from spreading.

Fireproof paint can be applied to indoor and outdoor projects, is easy to use, safe and does not take much construction time. This product also has excellent fire resistance, with the ability to withstand temperatures up to 1000 degrees Celsius for 3 hours, making it a very good fire prevention support material.

However, fireproof paint is not really popular in Vietnam and has a high price. In addition, if the temperature exceeds the limit, the fireproof coating will not prevent the fire for long.

With the above characteristics, fire-resistant paint is applied to projects such as airports, stations, stadiums, high-rise buildings or in factories that require fire resistance.

8. Fire-resistant glue

Fire-resistant glue is a product that applies modern and innovative production technology. Therefore, this material is both easy to construct, has high thermal insulation properties, and has the ability to prevent fire from spreading for up to 4 hours. This is considered a very effective solution to prevent fire from spreading through walls and floors.

The product can be applied in many different materials such as metal, electric cables, signal cables, plastic pipes…

9. Plasterboard

Plaster is also a popular fire-resistant material for Vietnamese people because the product has high aesthetics and diverse designs.

Plasterboard panels have relatively good durability (about 8 years on average), and also help reduce temperature, bringing coolness to the space.

However, this material has a major disadvantage: it is very hydrophobic, leading to the plasterboard being stained after a period of use and having unsightly cracks appear in places that have been plastered. bamboo shoots. In addition, the product’s heat insulation and fire resistance effectiveness is not highly appreciated compared to other materials.

Plasterboard is currently mainly applied to walls and ceilings, and can create partitions for companies, offices…

10. Fire-resistant wood

Wood is often known as a flammable material. However, with today’s developed technology, people have researched treating wood by using fire-retardant liquids and fire-retardant paints to ensure safety and prevent fire and explosion, and become a material to prevent the spread of fire.

When using fireproof wood for construction, the biggest advantage is that you will take advantage of the aesthetics and durability of wood while still ensuring its ability to withstand heat and catch fire. However, fireproof wood is only suitable for wooden doors and entrance areas and is not as flexible as other fireproof materials.